Atomically precise manufacturing — building

at the molecular scale with engineering control — is the

ultimate Grand Challenge of the National Nanotechnology Initiative.

Only a few years ago, this goal sounded like science fiction, but

recent scientific results show it is within our grasp, if we rise

to the challenge. Developing and commercializing this technology

will deliver substantial economic, social, defense, and health

benefits to our country—and society in general. Some frequently

asked questions and answers concerning this revolutionary technology

follow.

Atomically precise manufacturing is the ability

to manufacture materials and structures at the atomic or molecular

size scale. This technology integrates the knowledge and low

manufacturing cost of chemistry with the knowledge and flexibility

of engineering. The result is a manufacturing technology that

achieves the low cost of chemical manufacturing, combined with

the engineering mastery that brings us the microchip or suspension

bridges, and the flexibility and design freedom offered by computer

software. This future manufacturing technology will enable us

to make products in a cleaner, cheaper, and faster way than any

technology that exists today.

Self-assembly is a powerful process for creating

materials, and a number of research groups are experimenting in the

field. Zyvex will utilize some aspects of self-assembly, but the

core focus of our technical approach is to create engineered structures

by means of parallel, automated assembly of atoms under computer

control. This positionally-controlled chemistry allows us to achieve

the long-range order of molecular-scale building blocks that is vital

to atomically precise manufacturing. On the other hand, self-assembly

is sensitive to slight changes in the building blocks, making those

systems difficult to engineer. It also suffers from a lack of long-range

order. As an example, imagine building a 200-foot brick wall. A pure

self-assembly approach would start by randomly laying twenty bricks

and building up from each brick independently. One would soon find

that the random sections didn’t join with one another, and

the resulting brick wall would be weak and ugly. Zyvex’s ordered

approach to assembly would start by laying a foundation row of bricks,

and building up from there row by row. Long-range order is extremely

important to engineering strong, useful structures.

Actually we agree with Professor Smalley. However,

if you look carefully at what he has said, it does not apply to

our approach. Smalley believed that complex, floppy molecules cannot

be put together with atomic pick and place techniques. Our target

is not the kinds of molecules that living creatures make, but rather

rigid, crystalline structures comprised of a small number of elements.

Our approach will use parallel arrays of molecular-scale tools

operating with high precision to create extremely valuable devices

and structures with atomic precision.

Some implications of quantum mechanics are hard

to understand, which leads to certain myths about quantum uncertainty.

The uncertainty of any particle’s position is related to its

momentum (or mass), so while a light electron may have considerable

uncertainty in its position and momentum, an atom is much heavier

and tends to stay put (which also keeps its electrons nearby). If

atoms were as frisky as the “quantum uncertainty” critics

claim, solid objects would continually evaporate before our eyes

(in fact, life could not exist in such a universe).

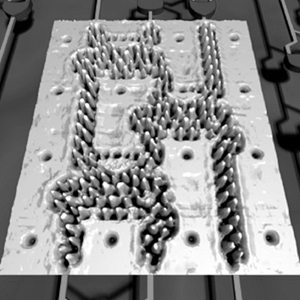

|

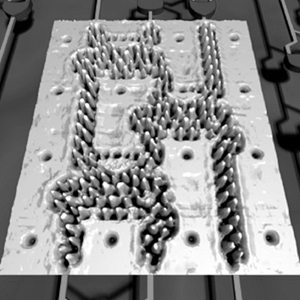

Figure

1.

IBM’s molecular cascade 3-input sorter. CO molecules are arranged

on Cu to perform a logic function.

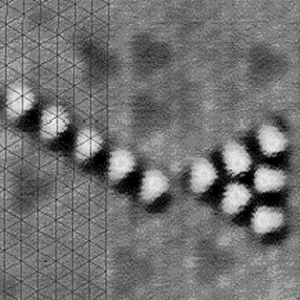

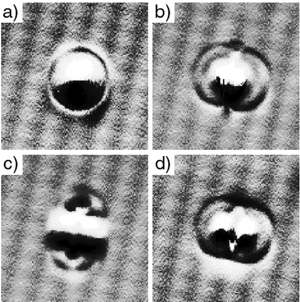

Figure 2.

Oxygen atoms arranged on Pt surface from “Single Molecule Dissociation

by Tunneling Electrons,” B.C. Stipe, M.A. Rezaei, W. Ho, S. Gao,

M. Mersson, and B.I. Lundqvist. Phys. Rev. Lett. 78 (1997): 4410-4413.

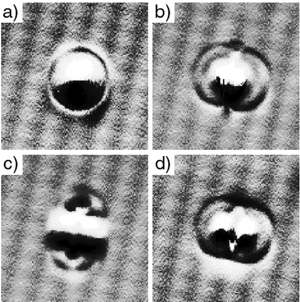

Figure

3.

Assembled Iron and Cu Carbonyls by Wilson Ho from “Structural Determination

by Single-Molecule Vibrational Spectroscopy and Microscopy: Contrast

Between Copper and Iron Carbonyls.” H.J. Lee and W. Ho, Phys. Rev.

B. 61 (2000): R16347-R16350.

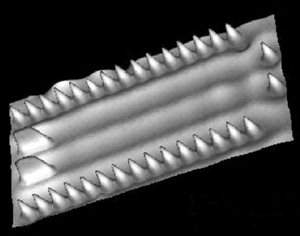

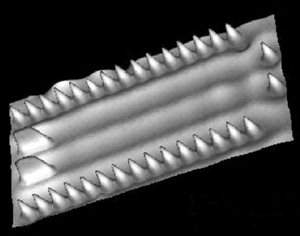

Figure

4.

Molecular accelerator created on Cu surface by Saw Hla, Ohio University.

|

Yes. The first clear demonstration of the arrangement of atoms was in

1990 when Don Eigler arranged 35 Xenon atoms to spell out IBM.1 Since

then, many groups have demonstrated the ability to manipulate atoms into

designed structures. Bob Celotta and Joe Stroscio of the National Institute

of Standards and Technology (NIST) have gone so far as to make the Autonomous

Atom Assembler that can create designed arrangements of atoms in a completely

automated fashion.2 Eigler’s team has

recently created molecular logic structures (see Figure 1 at left).

As a matter of fact, yes. Wilson Ho3 at UC

Irvine, and Saw Hla4 at Ohio University have

manipulated atoms and molecules to make and break chemical bonds (see

Figures 2 thru 4). Figure 3 shows a clear demonstration of what we call

mechanochemistry — where we can move atoms and molecules together

to deliberately make and break chemical bonds.

Yes, it has. Joe Lyding5 at the University

of Illinois Urbana-Champaign has shown that he can remove hydrogen atoms

adsorbed on atomically flat silicon surfaces. We refer to this as “atomic

precision depassivation.” Michelle Simmons6 at

the University of New South Wales has used this technique to place a

single phosphorous atom at an exact location in a silicon lattice to

form a “Qubit” (the fundamental computing element in quantum

computation). Lyding7 has recently shown

that he can control the growth of single layers of atoms with his depassivation

technique to make three-dimensional structures of crystalline silicon.

It is well known that atoms are in a state of constant motion due to

thermal noise. In liquids, small particles are jostled around by the

liquid molecules; an effect called “Brownian motion.” The “thermal

noise” critics claim it isn’t possible to build with atomic

precision due to this effect. However, careful analysis shows that stiff

structures can hold their position with high accuracy even in the presence

of thermal noise. This is proven by thousands of researchers worldwide

making atomic resolution pictures of atomic structures, and doing the

atomically precise manipulations described earlier. If we choose to make

our positioning devices with less stiffness, we can cool the environment,

which reduces thermal vibration to inconsequential levels. This is not

a problem that will stop our progress.

The most valuable structures that could be made with this technique would

be tools to enable modestly parallel initially, and then massively parallel

systems to produce atomically precise structures more cost effectively.

But there are many highly valuable very small structures that could be

made with a tool that could only assemble things one atom at a time.

One entire class of structures is designed to interact with specific

molecules. One example of this is a nanopore that would have the ability

to read DNA at up to one million bases per second.8,9 Atomically

precise tips for atomic force and scanning tunneling microscopes would

have a huge impact on metrology for the semiconductor industry and for

science in general. Earlier in this white paper, we mentioned qubit for

quantum computing.6 It takes just a handful

of qubits to do quantum encryption. There are many other highly valuable

products that one could create with early stage atomically precise manufacturing

tools.

|

Science fiction writers love to use a little pseudo-science to tell a good

story, but we shouldn’t confuse pseudo-science with reality. We intend

to build machines that help us manufacture things with atomic precision. This

is grounded in reality, as evidenced in the research we mentioned earlier.

Building self-aware machines that reproduce in the wild is science fiction,

and likely to remain that way for many decades, even at the macro scale. Nobody

knows how to do this sort of thing even with supercomputers, computerized machine

shops, and unlimited electric power, so worrying about doing it in specks too

small to see, powered by fuel cells we don’t even know how to make, reproducing

themselves by some unknown technology, and programmed by genius programmers

that haven’t even built a robot as smart as a worm, seems a waste of

worry.

1. D.

M. Eigler, E.K. Schweizer. Nature 334 (1990): 524.

2. Celotta and Stroscio, “AVS Symposium.” Nov

2003.

3. See twelve papers by Wilson Ho on controlling

chemistry at the atomic scale.

4. See eleven papers by Saw Hla on his work on chemistry

at the atomic scale.

5. See eight papers by Joe Lyding of hydrogen depassivation.

6. See ten papers by Michelle Simmons on constructions

of qubits.

7. Joe Lyding described Patterned ALE at the “AVS

Symposium.” March 2003.

8. Dan Branton, Harvard. http://www. mcb.harvard.edu/brantonindex.htm.

9. Viktor Stolc. “Nanopores for Gene Sequencing.” Proposal.

NASA Ames Research Center.

• L.J. Lauhon and

W. Ho, “The Initiation and Characterization of Single Bimolecular

Reactions with a STM.” Faraday Discussion 117 (2000): 249-255.

• L.J. Lauhon and W. Ho. “Inducing and Observing the Abstraction

of a Single Hydrogen Atom in Bimolecular Reaction with a Scanning Tunneling Microscope.” J.

Phys. Chem. 105 (2000): 3987-3992.

• G. V. Nazin, X. H. Qiu, and W. Ho. “Visualization and Spectroscopy

of a Metal-Molecule-Metal Bridge.” Science 302 (2003): 77-81. Published

online September 4, 2003; 10. 1126/Science. 1088971.

• T. M. Wallis, N. Nilius, and W. Ho. “Single Molecule Vibrational

and Electronic Analyses of the Formation of Inorganic Complexes: CO Bonding to

Au and Ag Atoms on NiAl [110].”

J. Phys. Chem. 119 (2003): 2296-2300.

• N. Nilius, T. M. Wallis, and W. Ho. “Vibrational Spectroscopy and

Imaging of Single Molecules: Bonding of CO to Single Palladium Atoms on NiAl[110].” J.

Phys. Chem. 117 (2002): 10947-10952.

• W. Ho. “Single Molecule Chemistry.” J. Phys. Chem. 117 (2002):

11033-11061.

• T. M. Wallis, N. Nilius, and W. Ho. “Electronic Density Oscillations

in Gold Atomic Chains Assembled Atom by Atom.” Phys. Rev. Lett., 89 (2002):

236802.

• J.R. Hahn and W. Ho. “Oxidation of a Single Carbon Monoxide Molecule

Manipulated and Induced with a Scanning Tunneling Microscope.” Phys. Rev.

Lett. 87 (2001): 166102.

• L.J. Lauhon and W. Ho. “Single Molecule Chemistry and Vibrational

Spectroscopy: Pyridine and Benzene on Cu [001].” J. Phys. Chem. A, 104

(2000): 2463-2467.

• L.J. Lauhon and W. Ho. “Control and Characterization of a Multi-step

Unimolecular Reaction.” Phys. Rev. Lett. 84 (2000): 1527-1530.

• H.J. Lee and W. Ho. “Single Bond Formation and Characterization

with a Scanning Tunneling Microscope.” Science, 286 (1999): 1719-1722.

• B.C. Stipe, M.A. Rezaei, W. Ho, S. Gao, M. Persson, and B.I. Lundqvist. “Single

Molecule Dissociation by Tunneling Electrons.” Phys. Rev. Lett., 78, 4410.

• S.W. Hla, K.F.

Braun, K.H. Rieder. Phys. Rev. B, 67 (2003): 201402(R).

• S.W. Hla, K.H. Rieder. Ann. Rev. Phys. Chem. 54 (2003): 307-330.

• S.W. Hla, G. Meyer, K.H. Rieder. Chem. Phys. Lett. 370 (2003): 431-436.

• S.W. Hla. “Nanoscale spectroscopy and its application in semiconductor

research.” Edited by Y. Watanabe, S. Heun, G. Salviati, N. Yamamoto. Lecture

Notes in Physics (Springer Verlag Heidelberg), (2002): 222-230.

• S.W. Hla, K.H. Rieder. “Superlattices & Microstructures.” 31

(2002): 63-72.

• A. Kühnle, G. Meyer, S.W. Hla, K.H. Rieder. Surf. Sci. 499 (2002):

15-23.

• G. Meyer, F. Moresco, S.-W. Hla, J. Repp, K.-F. Braun, S. Foelsch, K.H.

Rieder. Jap. J. Appl. Phys. 40 (2001): 4409-4412.

• S.W. Hla, G. Meyer, K.H. Rieder. “Inducing Single Molecule Chemical

Reactions with STM: A New Dimension for Nano-Science and Technology.” Chem

Phys Chem. 2 (2001): 361-366.

• S.W. Hla, L. Bartels, G. Meyer, K.H. Rieder. “Inducing all steps

of a chemical reaction with the scanning tunneling microscope tip: Towards single

molecule engineering.” Phys. Rev. Lett. 85 (2000): 2777-2780.

• S.W. Hla, A. Kuhnle, G. Meyer, K.H. Rieder. “Controlled lateral

manipulation of single diiodo-benzene molecules on the Cu surface with the tip

of a scanning tunneling microscope.” Surf. Sci. 454-456 (2000): 1079.G.

Meyer, J. Repp, S. Zöphel, K.F. Braun, S.W. Hla, S. Fölsch, L. Bartels,

F. Moresco, K.H. Rieder. “Controlled manipulation of atoms and small molecules

with a low temperature scanning tunneling microscope.” Single Molecule

1 (2000): 79-86.

• M. C. Hersam,

N. P. Guisinger, and J.W. Lyding. “Silicon-based molecular

nanotechnology.” Nanotechnology 11 (2000): 70.

• G.C. Abeln, M.C. Hersam, D.S. Thompson, S.T. Hwang, H. Choi, J.S. Moore,

and J.W. Lyding. “Approaches to Nanofabrication on Si Surfaces: Selective

Area CVD of Metals and Selective Chemisorption of Organic Molecules.” J.

Vac. Sci. Technol. B 16 (1998): 3874.

• M. C. Hersam, J. Lee, N. P. Guisinger, and J.W. Lyding. “Implications

of atomic-level manipulation on the Si [100] surface: From enhanced CMOS reliability

to molecular nanoelectronics.” Superlattices and Microstructures 27 (2000):

583.

• M.C. Hersam, G.C. Abeln, and J.W. Lyding, “An Approach for Efficiently

Locating and Electrically Contacting Nanostructures Fabricated via UHV-STM Lithography

on Si [100].” Micro-electronic Engineering 47 (1999): 235.

• I.C. Kizilyalli, K. Hess, and J.W. Lyding, “Channel Hot Electron

Degradation-delay in MOS Transistors Due to Deuterium Anneal.” The VLSI

Handbook Chapter 13. CRC Press LLC. (1999).

• J. Lee, Y. Epstein, A.C.erti, J. Huber., K. Hess, and J.W. Lyding. “The

Effect of Deuterium Passivation at Different Steps of CMOS Processing on Lifetime

Improvements of CMOS Transistors,” IEEE Transactions on Electron Devices,

46 (1999): 1812.

• J.W. Lyding, K. Hess, G.C. Abeln, G.C. Thompson, J.S. Moore, M.C. Hersam,

E.T. Foley, J. Lee, Z. Chen, S.T. Hwang, H. Choi, P.H. Avouris, and I.C. Kizilyalli, “UHV-STM

Nano-fabrication and Hydrogen/Deuterium Desorption from Silicon Surfaces: Implications

for CMOS Technology,” Applied Surface Science, 130-132 (1998): 221.

• Foley, E. T., Kam, A. F., Lyding, J. W., and Avouris, P. H. “Cryogenic

UHV-STM Study of Hydrogen and Deuterium Desorption from Si [100],” Physical

Review Letters, 80/6 (1998): 1336-1339.

• J.L. O’Brien,

S.R. Schofield, M.Y. Simmons, R.G. Clark, A.S. Dzurak, N.J. Curson,

B.E. Kane, N.S. McAlpine, M.E Hawley and G.W. Brown. “Towards

the fabrication of phosphorus qubits for a silicon quantum computer”,

Phys. Rev. B, 64 (2001): 161401.

• L. Oberbeck, N.J. Curson, M.Y. Simmons, R. Brenner, A.R. Hamilton, S.R.

Schofield and R.G. Clark. “Encapsulation of phosphorus dopants in silicon

for the fabrication of a quantum computer.” Applied Physics Letters 81

(2002): 3197.

• A.S. Dzurak, M.Y. Simmons, A.R. Hamilton, R.G. Clark, R. Brenner, T.M.

Buehler, N.J. Curson, E. Gauja, R.P. Mckinnon, L.D. Macks, M. Nitic, J.L. O’Brien,

L. Oberbeck, D.J. Reilly, S.R. Schofield, F.E. Stanley, D.N. Jamieson, S. Prawer,

C. Yang and G.J. Milburn/ “Construction of a silicon-based solid state

quantum computer.” Quantum Information and computation 1 (2001): 82.

• J.L. O’Brien, S.R. Schofield, M.Y. Simmons, R.G. Clark, A.S. Dzurak,

N.J. Curson, B.E. Kane, N.S. McAlpine, M.E. Hawley and G.W. Brown. “Nanoscale

phosphorus atom arrays created using STM for the fabrication of a silicon based

quantum computer.” BioMEMS and Smart Nanostructures 4590 (2001): 299.

• J.L. O’Brien, S.R. Schofield, M.Y. Simmons, R.G. Clark, A.S. Dzurak,

N.J. Curson, B.E. Kane, N.S. McAlpine, M.E. Hawley, and G.W. Brown. “Scanning

tunneling microscope fabrication of arrays of phosphorus atom qubits for a silicon

quantum computer.” Smart Materials and Structures 11 (2002): 741.

• M.E. Hawley, G.W. Brown, M.Y. Simmons and R.G. Clark. “Fabricating

a qubit array with a scanning tunneling microscope.” Los Alamos Science

27 (2002): 302.

• M. Y. Simmons, S. R. Schofield, J. L. O’Brien, N. J. Curson, L.

Oberbeck, T. Hallam and R. G. Clark. “The atomic-scale fabrication of a

solid-state silicon based quantum computer.” Surface Science. July 2002.

• N.J. Curson, S.R. Schofield, M.Y. Simmons, L. Oberbeck and R.G. Clark. “Critical

issues in the formation of atomic arrays of phosphorus in silicon for the fabrication

of a solid-state quantum computer.”Surface Science. July 2002.

• L. Oberbeck, N.J. Curson, M.Y. Simmons, S.R. Schofield and R.G. Clark, “Challenges

in surfaces for quantum computing.” Surface Review and Letters. August

2002.

• L. Oberbeck, T. Hallam, N.J. Curson, M.Y. Simmons and R.G. Clark, “Epitaxial

silicon growth in the presence of hydrogen.” Applied Surf. Sci. (2002).

© 2004-2010,

Zyvex Labs, LLC. |